The Enduring Strength of Die Cast Metal in Construction Equipment

Related Articles: The Enduring Strength of Die Cast Metal in Construction Equipment

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Enduring Strength of Die Cast Metal in Construction Equipment. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Enduring Strength of Die Cast Metal in Construction Equipment

Die cast metal construction equipment has long been a mainstay in the construction industry, its robust nature and durability proving invaluable in demanding environments. This article delves into the intricacies of this technology, exploring its significance, benefits, and applications within the construction landscape.

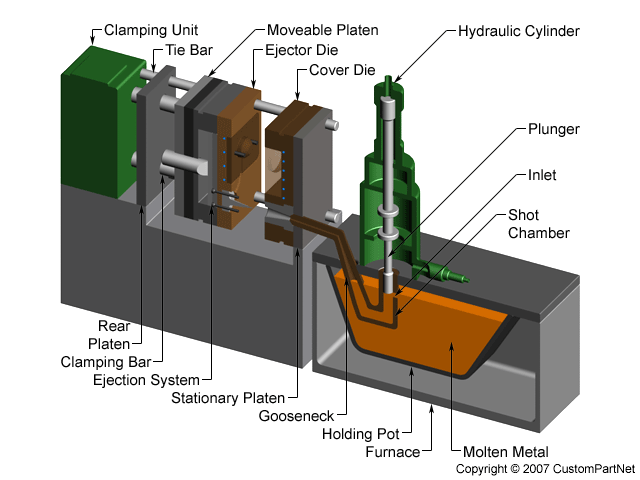

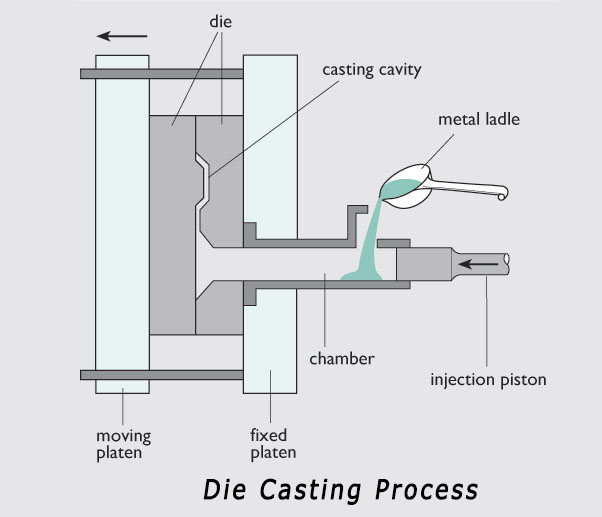

Understanding Die Casting: A Precision Manufacturing Process

Die casting, a high-pressure metal casting process, involves injecting molten metal into a reusable mold (die) to create intricate and complex components. This technique, widely used in the construction equipment industry, offers several advantages over traditional casting methods:

- High Production Rates: Die casting enables rapid production of identical components, streamlining manufacturing processes and increasing efficiency.

- Complex Geometries: The intricate designs of die molds allow for the creation of complex shapes and detailed features, often impossible with other casting methods.

- Dimensional Accuracy: Die casting produces parts with high dimensional accuracy and tight tolerances, ensuring consistent performance and assembly.

- Strong and Durable Components: The high pressure used in die casting creates dense, strong, and durable components, ideal for the demanding applications in construction equipment.

- Cost-Effectiveness: While initial tooling costs can be significant, die casting offers long-term cost savings through high production rates and reduced machining requirements.

A Deep Dive into Die Cast Metal Construction Equipment

Die cast metal finds its way into a wide array of construction equipment components, contributing significantly to their functionality and longevity. Here are some notable examples:

- Engine Components: Die casting plays a crucial role in manufacturing vital engine components like cylinder heads, valve covers, and oil pans. The process ensures precise dimensions and consistent performance, vital for the smooth operation of engines in heavy-duty applications.

- Transmission Components: Gear housings, shafts, and other transmission components benefit from the durability and precision offered by die casting. These components experience significant wear and tear, and die casting ensures their resilience and extended service life.

- Hydraulic Components: Die cast components, like hydraulic pumps and valve bodies, are essential for the efficient operation of hydraulic systems. The process allows for the creation of complex geometries and tight tolerances, crucial for the precise control and power delivery in hydraulic systems.

- Chassis and Frame Components: Die cast components are used in the construction of chassis and frames, providing strength and rigidity. These components are subjected to heavy loads and vibrations, and die casting ensures their structural integrity and resistance to fatigue.

- Cab Components: Die cast components, such as door handles, window frames, and dashboard components, enhance the durability and aesthetics of construction equipment cabs. The process allows for intricate designs and finishes, contributing to a comfortable and safe working environment.

Benefits of Die Cast Metal Construction Equipment

Beyond its applications, die cast metal construction equipment offers several benefits that contribute to its widespread adoption:

- Enhanced Durability and Longevity: The high strength and durability of die cast components contribute to the overall longevity of construction equipment, reducing the need for frequent repairs and replacements.

- Improved Performance and Efficiency: Precisely manufactured components, thanks to die casting, ensure smooth operation and efficient performance, maximizing productivity and minimizing downtime.

- Reduced Maintenance Costs: The robust nature of die cast components translates to reduced maintenance requirements, leading to lower operating costs and increased profitability.

- Enhanced Safety: The reliable performance and structural integrity of die cast components contribute to a safer working environment for operators and personnel.

- Environmental Sustainability: Die casting often utilizes recycled materials, promoting sustainability and reducing waste in the manufacturing process.

FAQs on Die Cast Metal Construction Equipment

1. What are the primary advantages of using die cast metal in construction equipment?

Die cast metal offers several advantages, including high production rates, complex geometries, dimensional accuracy, strength and durability, and cost-effectiveness. These advantages translate to improved performance, reduced maintenance, and increased longevity of construction equipment.

2. What are some common applications of die cast metal in construction equipment?

Die cast metal is used in a wide range of construction equipment components, including engine parts, transmission components, hydraulic components, chassis and frame components, and cab components.

3. What are the potential drawbacks of using die cast metal in construction equipment?

While die casting offers numerous benefits, there are some potential drawbacks. The initial tooling costs can be significant, and the process may not be suitable for all applications, especially those requiring large component sizes.

4. How does die casting contribute to the sustainability of the construction equipment industry?

Die casting often utilizes recycled materials, reducing waste and promoting environmental sustainability. Additionally, the durability and longevity of die cast components lead to fewer replacements, further contributing to a more sustainable industry.

5. What are the future trends in the use of die cast metal in construction equipment?

The future of die cast metal in construction equipment is promising. Advancements in die casting technology, including the use of lightweight alloys and innovative designs, are expected to further enhance the performance and sustainability of construction equipment.

Tips for Utilizing Die Cast Metal Construction Equipment

- Proper Maintenance: Regular maintenance, including lubrication and cleaning, ensures optimal performance and extends the lifespan of die cast components.

- Correct Operation: Operating construction equipment according to manufacturer specifications and best practices minimizes wear and tear on die cast components.

- Material Selection: Choosing the appropriate die cast metal alloy based on the specific application ensures optimal strength and durability.

- Design Optimization: Collaborating with experienced die casting engineers to optimize component designs for improved performance and reduced material usage.

- Quality Control: Implementing rigorous quality control measures throughout the manufacturing process ensures the production of high-quality die cast components.

Conclusion

Die cast metal construction equipment continues to play a vital role in the industry, offering a combination of strength, durability, and efficiency that is unmatched by other manufacturing processes. As technology advances, die casting is poised to become even more integral to the future of construction equipment, contributing to improved performance, sustainability, and safety in the demanding world of construction.

![Figure 3. Equipment and process of die casting for fabricating aluminum alloy pistons [33] CASTMAN](https://castman.co.kr/wp-content/uploads/Figure-3.-Equipment-and-process-of-die-casting-for-fabricating-aluminum-alloy-pistons-33.png)

Closure

Thus, we hope this article has provided valuable insights into The Enduring Strength of Die Cast Metal in Construction Equipment. We appreciate your attention to our article. See you in our next article!